HELIOS tubular heating elements offer numerous technological benefits. These include high levels of operational safety, dielectric strength, contact and moisture protection, good heat conduction and thermal conductivity, low thermal absorption, good deformability, high stability, shock resistance and long service life.

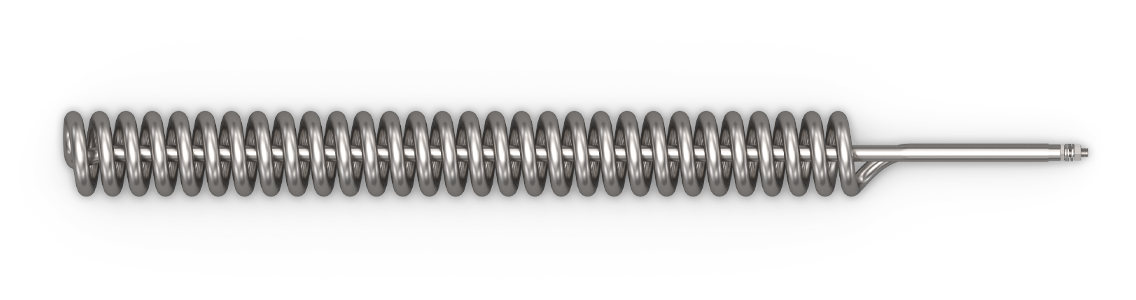

VERSATILE TUBULAR HEATING ELEMENTS.

HIGH PERFORMANCE TUBULAR HEATING ELEMENTS ARE MANUFACTURED IN ACCORDANCE WITH YOUR SPECIFICATION WITH INDIVIDUAL LENGTH, UNHEATED ZONE, VOLTAGE AND POWER. INDIVIDUAL. VERSATILE. SOPHISTICATED.

TECHNICAL DATA:

DESIGN:

High performance tubular heating elements, diameter 8.4 in accordance with DIN 44874 comprise a spiralled heating element with welded-on M4 connecting bolt, embedded centrally in a highly-compressed insulating compound made of magnesium oxide and protected by a bendable metal tube.

The tube ends are closed off with sealing ceramic end caps.

Depending on the application, heating conductors are NiCr 3020 or NiCr 8020.

Immersion length up to 3,500 mm possible.

VOLTAGE:

Up to 690 Volt.

POWER:

Depending on application

LOAD:

A table for determination of the maximum surface load and tube sheath material can be found on page 9.1.6 of the product catalogue. Please get in touch with us. We will be glad to advise you.

Materials of the tubular heating element:

| Mat. no. 1.0108 | Steel | |

| Mat. no. 1.4404: | AISI 316L | Stainless steel, corrosion-resistant |

| Mat. no. 1.4541: | AISI 321 | Stainless steel, max. temp. 750 °C |

| Mat. no. 1.4571: | AISI 316Ti | Stainless steel, corrosion-resistant |

| Mat. no. 1.4828: | AISI 309 | Stainless steel, max. temp. 850 °C |

| Mat. no. 1.4876: | ALLOY 800 | Stainless steel, corrosion and temperature-resistant |

| Mat. no. 2.4858: | ALLOY 825 | Special material, high degree of corrosion resistance |

| Mat. no. 3.7035: | Titanium, high degree of corrosion resistance |

LET`S WORK

TOGETHER.

We are delighted that you are interested in our products and are available to answer your questions at any time. We will be glad to advise you and provide you with a personal offer, tuned to your application. Write us an email or simply call us at: +49 2392 6908 0